PP spunbond nonwoven fabrics find applications in a wide range of industries due to their versatility, durability, and cost-effectiveness.

Here are some examples of industries that commonly use PP spunbond nonwoven fabrics:

Hygiene Products: PP spunbond nonwoven fabrics are extensively used in the production of hygiene products such as diapers, sanitary napkins, adult incontinence products, and baby wipes. These fabrics provide softness, breathability, and liquid absorption properties.

Medical and Healthcare: PP spunbond nonwoven fabrics are used in various medical and healthcare applications, including surgical gowns, masks, caps, shoe covers, drapes, and medical bedding. These fabrics offer barrier properties, high strength, and comfort.

Agriculture: PP spunbond nonwoven fabrics are employed in agriculture for crop protection and mulching applications. They are used as crop covers to protect plants from insects, wind, and frost. Additionally, they are used as mulch mats to control weed growth and retain moisture in soil.

Geotextiles: PP spunbond nonwoven fabrics are utilized in geotextile applications for erosion control, soil stabilization, and drainage. They are used in road construction, landfills, embankments, retaining walls, and erosion control blankets.

Filtration: PP spunbond nonwoven fabrics are employed in various filtration applications, including air filters, liquid filters, dust bags, and automotive filters. These fabrics offer high filtration efficiency, durability, and resistance to chemicals.

Packaging: PP spunbond nonwoven fabrics are used in packaging applications such as tote bags, shopping bags, and gift wraps. They provide strength, tear resistance, and can be customized with attractive prints.

Furniture and Bedding: PP spunbond nonwoven fabrics find use in the furniture and bedding industry. They are utilized as upholstery fabrics, mattress covers, pillow covers, and bed linens. These fabrics offer durability, breathability, and comfort.

Automotive: PP spunbond nonwoven fabrics are employed in the automotive industry for applications such as car interiors, trunk linings, door panels, and engine covers. They offer sound absorption, thermal insulation, and resistance to wear and tear.

Construction: PP spunbond nonwoven fabrics are used in the construction industry for applications like insulation, roofing underlays, wall coverings, and concrete reinforcement. They provide strength, moisture control, and protection against UV radiation.

These are just a few examples of industries that commonly use PP spunbond nonwoven fabrics. The versatility and wide range of properties exhibited by these fabrics make them suitable for various applications across different sectors.

How are PP spunbond nonwoven fabrics used in erosion control and soil stabilization in geotextile applications?PP spunbond nonwoven fabrics are widely used in geotextile applications for erosion control and soil stabilization purposes.

Here’s how they are utilized in these applications:

Erosion Control: PP spunbond nonwoven fabrics are employed to prevent soil erosion in areas where vegetation is not yet established or cannot be maintained. They are typically used in the following ways:

Slope Stabilization: The fabric is installed on slopes to prevent soil erosion caused by rainfall, wind, or water flow. It acts as a barrier, holding the soil in place and preventing it from being washed away.

Channel Protection: PP spunbond nonwoven fabrics can be placed along rivers, streams, or drainage channels to protect the banks from erosion caused by water flow. They help dissipate the energy of the flowing water and reduce the impact on the soil.

Coastal Protection: In coastal areas, where erosion is a significant concern, PP spunbond nonwoven fabrics can be used to stabilize beaches, dunes, and coastal embankments. They help trap sand and prevent it from being carried away by waves and currents.

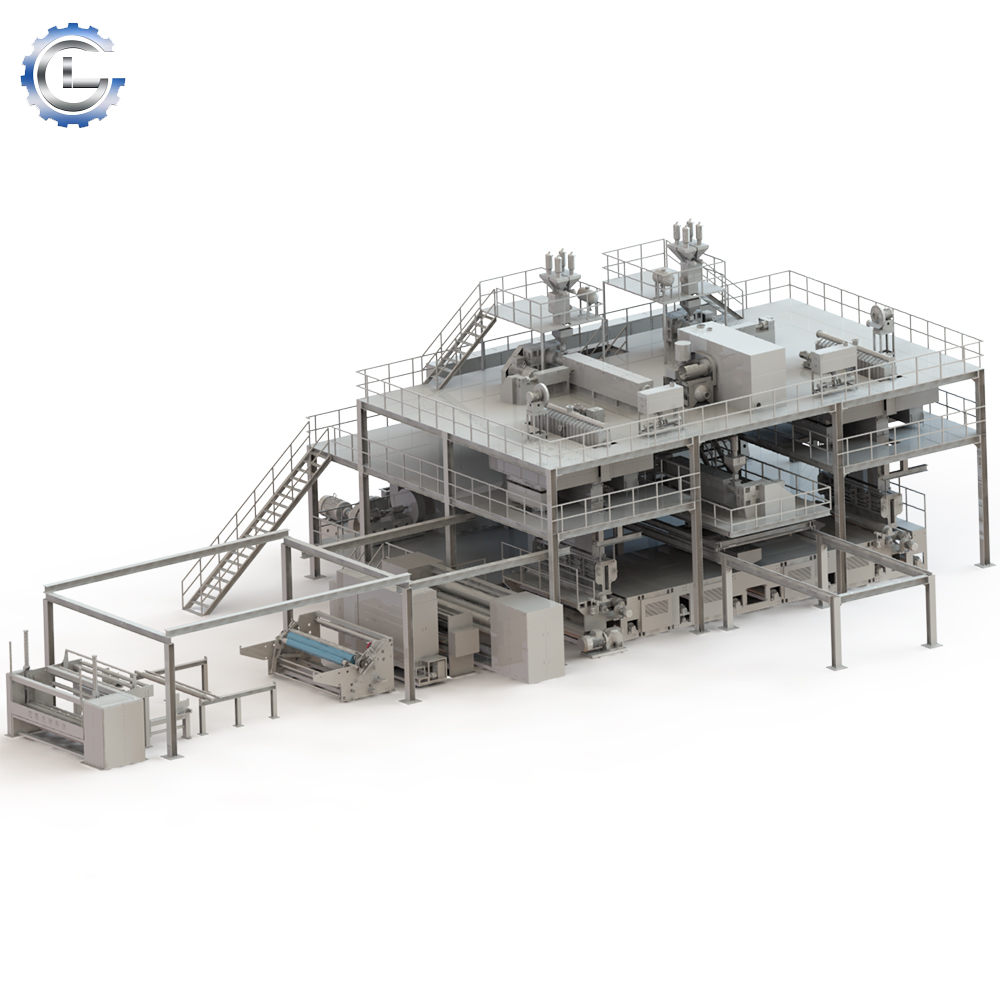

Soil Stabilization: PP spunbond nonwoven fabrics are used to enhance the stability and load-bearing capacity of soils. PP S Spunbond Machine They provide reinforcement and confinement to the soil, improving its structural integrity. Some common applications include:

Road and Railway Construction: PP spunbond nonwoven fabrics are employed in road and railway construction projects as a geotextile layer beneath the pavement or ballast. They help distribute the load, reduce soil movement, and prevent the mixing of different soil layers.

Retaining Walls: In the construction of retaining walls, PP spunbond nonwoven fabrics can be used to reinforce the soil and prevent its movement. They are placed between the soil layers to provide stability and prevent soil loss.

Landfill Capping: PP spunbond nonwoven fabrics are utilized in landfill capping systems to prevent the infiltration of water into the waste and control gas emissions. They act as a barrier between the waste and the cover soil, providing stability and protecting the environment.

Embankment Stabilization: PP spunbond nonwoven fabrics can be used to reinforce embankments and steep slopes. They help distribute the load and reduce the risk of slope failure, providing stability and preventing soil erosion.

In erosion control and soil stabilization applications, PP spunbond nonwoven fabrics offer several advantages. They have high tensile strength, good puncture resistance, and excellent filtration properties. They are permeable, allowing water to pass through while retaining soil particles. Additionally, these fabrics are resistant to UV degradation, chemicals, and biological degradation, making them suitable for long-term geotextile applications.