Bricks are fundamental building materials renowned for their durability, strength, and resilience in construction. Understanding the properties of bricks, including their melting point, is crucial in ensuring their stability and suitability for various applications, particularly in environments subject to high temperatures.

The Composition of Bricks

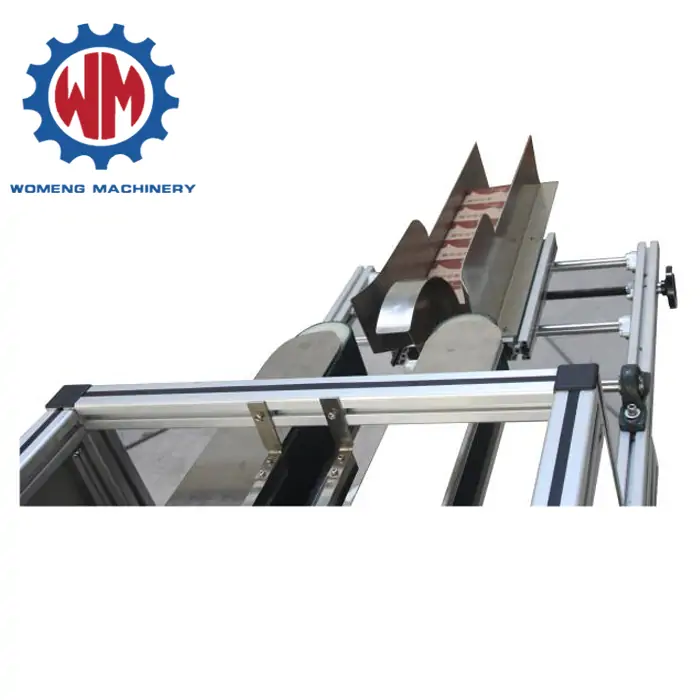

- Clay and Shaping: Bricks are primarily made from clay, molded into specific shapes, and then fired at high temperatures to create solid, durable units used in construction.

- Additives and Firing: Depending on the type of brick, various additives or minerals might be included in their composition. These bricks undergo firing in kilns at elevated temperatures, altering their physical and chemical properties.

Melting Point of Bricks

- Temperature Resistance: Bricks are heat-resistant materials with relatively high melting points due to the firing process during their manufacture. The typical melting point of standard construction bricks ranges from about 2,000 to 2,700 degrees Fahrenheit (1,100 to 1,500 degrees Celsius).

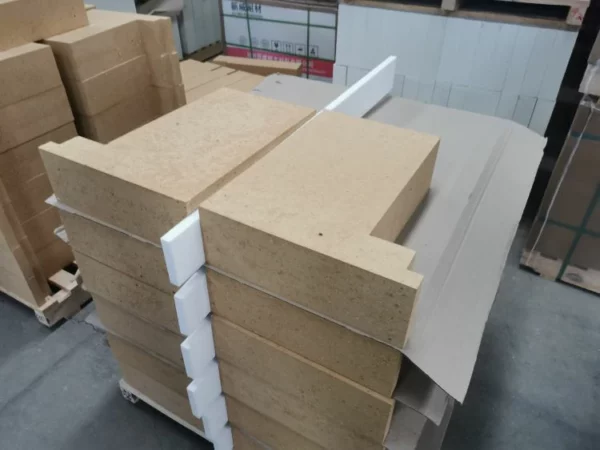

- Variation Based on Composition: The melting point can vary based on the type of brick and the materials used in its composition. For instance, refractory bricks used in high-temperature applications, such as furnaces or kilns, have higher melting points and greater thermal stability.

Application and Thermal Stability

- Structural Integrity: Bricks’ high melting point ensures their structural integrity in various building elements, providing stability even in environments exposed to high temperatures.

- Fire Resistance: In fire-prone environments, bricks offer excellent fire resistance due to their ability to withstand high temperatures without compromising their structural integrity.

Factors Influencing Melting Point

- Type of Brick: Different types of bricks, such as firebricks or refractory bricks, are specifically engineered with higher melting points to withstand extreme heat, catering to specific construction needs.

- Firing Process: The temperature and duration of the firing process during brick manufacturing significantly impact their melting points and thermal stability.

Importance in Construction

- Structural Safety: Understanding the melting point of bricks ensures the safety and structural stability of buildings in environments where elevated temperatures are a concern.

- Fire Protection: Bricks’ resistance to high temperatures contributes significantly to fire protection measures in buildings, minimizing the spread of fires and enhancing safety.

The melting point of bricks plays a pivotal role in determining their thermal stability and suitability for various construction applications. Bricks’ resistance to high temperatures, attributed to their firing process and composition, ensures their structural integrity and fire resistance, making them indispensable in creating durable, safe, and resilient buildings. Understanding their thermal properties empowers architects, engineers, and builders to make informed decisions regarding the use of bricks in construction, ensuring the safety and longevity of structures in diverse environments.